ENGINEERED IN SWITZERLAND HAND CRAFTED IN ITALY

This isn’t just a frame. It’s your frame. Built for the way you ride. The power you put down. The feel you want beneath you. Whether that’s razor-sharp responsiveness, all-day comfort, or something perfectly in between. From that first moment you hit the road, the feeling of excitement, the bike becoming an extension of your body — perfectly tuned, in perfect harmony. It’s not just riding; it’s a pure, uninterrupted connection with the road that you feel.

SWI is the only custom frame builder who tailors the carbon lay up of each frame to the individual rider based on the rider’s weight, power output and desired ride feel. When this is combined with our unique use of a Unishell Monocoque Frame we believe this delivers the best combination of geometric accuracy, comfort and reactivity that it is possible to create.

100% Geometric Accuracy

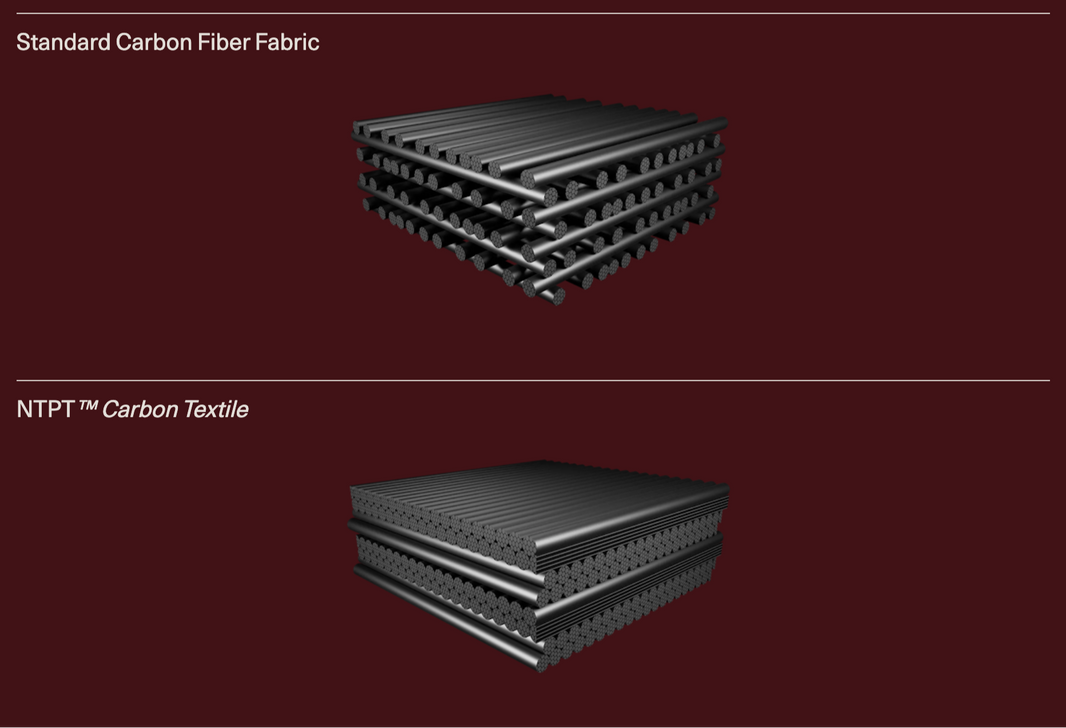

To deliver the required stiffness to comfort ratio we adjust the number of TPT carbon layers in key areas of the frame (e.g bottom bracket, head tube, chain stays). This is possible because 1mm of TPT carbon textile has 14 layers of carbon verses the 5 layers of standard carbon fiber – we therefore have considerable freedom to adjust the number of layers to meet the rider’s desired ride feel.

Unlike traditional custom frame builders or modular monocoque manufacturers who have to glue tubes & lugs or front & rear triangles together, every SWI frame is 100% geometrically accurate as there is no frame assembly. A SWI frame comes out of the mould in one uninterrupted carbon shell.

No breaks, no seams.

Just one flowing unit that moves with you. It’s like the bike disappears and all that’s left is you and the road, connected in a way you’ve never felt before.

Unishell Monocoque Carbon Shell

SWI is unique in building Unishell Monocoque carbon bicycle frames. A Unishell Monocoque is a frame that is one uninterrupted carbon shell formed in a single mould. This method is complex, time consuming and expensive, however:

1. It enables the unidirectional carbon fibers to be connected all around the frame without any obstruction, reducing vibrations and resulting in the most efficient transfer of power from pedal stroke into forward motion.

2. It produces a frame of unbeatable structural integrity, geometric accuracy and precision, which is especially noticeable when cornering at speed.

Thin Ply Technology Carbon Textile

TPT is the DNA and power behind every SWI frame. An exceptionally dense carbon textile made by the Swiss company North Thin Ply Technology, it is used for carbon yacht racing sails, race yacht foils, the carbon chassis of F1 cars and Moto GP superbikes.

In 1mm of thickness there are 14 layers of carbon, compared to the standard carbon fiber used in bicycle frame building which only has 5 layers. Each individual micro layer of TPT is precisely aligned in 4 different directions: 0, 90, +45, -45 degrees to add further strength.

The TPT is then impregnated with a special resin that allows for high pressure moulding at 6 bars in an Autoclave airtight oven, compressing the carbon fibers significantly beyond standard carbon frames, producing unmatched strength, durability and safety whilst minimizing weight. The result is a frame possessing an exceptional stiffness to weight ratio, creating a noticeably reactive ride feel.

The internal layers of the AEQUUS are all TPT carbon textile. The final visible layer is 3K herringbone carbon textile which we apply for added comfort and aesthetics.

THIS IS THE RIDE

YOU'VE BEEN WAITING FOR

At SWI, we don’t just build bikes—we craft an experience that’s uniquely yours. We listen to what you want: the way you want to feel the road beneath you, the way you want to connect with every turn, every climb, every descent.

This isn’t just a ride. This is a connection, a journey. A relationship with the road, the bike, and yourself. It’s your invitation to feel what you've always dreamed of. The result? A frame that doesn't just fit your body—it fits your ride soul.

DON'T JUST DREAM IT. OWN IT.